Taking Apart Powerful Machines of War from Airplanes to Submarines

Welcome to the ultimate teardown tour, where we rip apart the world’s mightiest war machines, from jaw-dropping airplanes to stealthy submarines. Ever wondered what makes a fighter jet roar or how a sub stays hidden beneath the waves? Buckle up and get ready to dive deep into the guts of these powerful machines. It’s not just about the nuts and bolts—it’s about the tech, the tricks, and the heart-pounding action that makes these machines tick.

Piecing Together the Power

Imagine peeking inside a jet engine like you’re unwrapping a super-complicated present. First up, you’ve got the turbines, which are like the heart of the engine, spinning at insane speeds to push the jet forward. Next wiki, there’s the compressor, a sneaky part that squashes air to make it hotter and more powerful. Don’t forget the nozzles, which control the direction of the engine’s blast to help the plane steer and accelerate like a boss.

Upgrades and Innovations:

So, next time you see a jet soaring through the sky, remember there’s a complex world of technology and maintenance keeping it in the air. From the roar of the turbines to the fine-tuning of the control systems, every part of a jet engine is engineered for peak performance.

Dissecting Airborne Tech

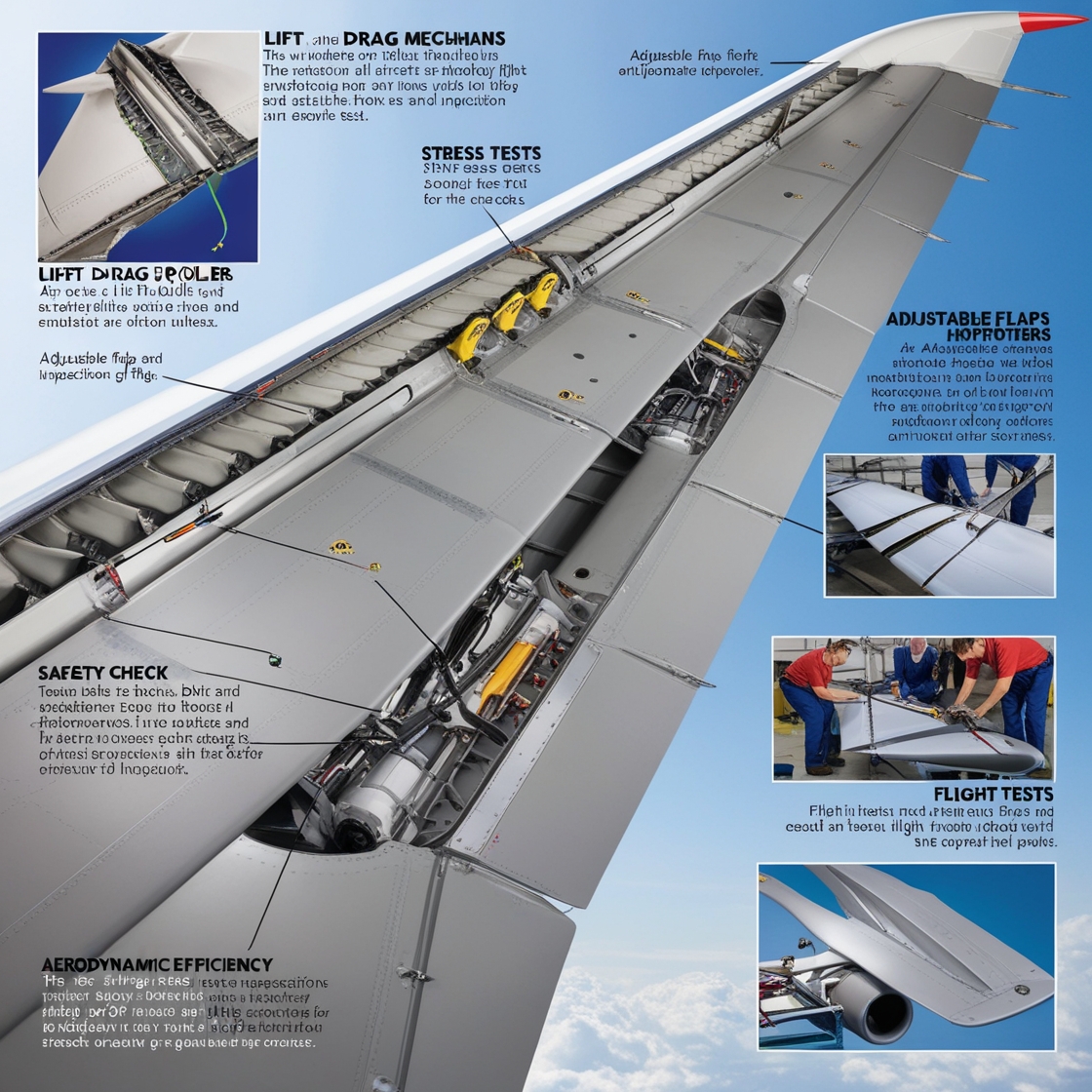

Wings aren’t just for show—they’re the secret sauce behind how planes fly. The first thing you need to know is lift, which is what keeps the plane off the ground. Wings are designed to create a pressure difference between the top and bottom surfaces, which pushes the plane upward. Then there’s drag, the force that tries to slow the plane down. The shape of the wing, called the airfoil, is designed to minimize drag and maximize lift.

Safety Checks:

-

Structural Integrity:

-

Perform stress tests to ensure wing strength.

-

Check for any signs of fatigue or cracking.

-

Ensure all bolts and fasteners are secure.

-

Aerodynamic Efficiency:

-

Test wings for lift and drag performance.

-

Adjust aerodynamic surfaces for optimal flight.

-

Monitor for any changes in flight stability.

-

Flight Testing:

-

Conduct test flights to validate wing performance.

-

Simulate different flight conditions and maneuvers.

-

Gather data for further adjustments if needed.

Now, let’s talk flaps. These little guys are like the plane’s adjustable gadgets. Slats help the wing handle slow speeds, ailerons control roll, and spoilers are like the plane’s brakes in the sky. When you’re diving into wing surgery, you’re dealing with repairs and replacements for these critical parts. Whether it’s fixing a dent or replacing a flap, keeping wings in top condition is key to safe flying.

The Control Center Craze

The cockpit is like the nerve center of an airplane, packed with dials, screens, and controls that help pilots navigate the skies. Picture the dashboard news of a high-tech sports car but on steroids. You’ve got the yoke, which controls the plane’s pitch and roll, the pedals for steering, and the throttles to manage engine power. Each of these controls plays a vital role in maneuvering the plane.

Training and Simulation:

-

Cockpit Simulators:

-

Provide realistic flight training experiences.

-

Allow pilots to practice emergency procedures.

-

Simulate various flight conditions and scenarios.

-

Control Calibration:

-

Regularly adjust controls for accurate responses.

-

Ensure feedback mechanisms are functioning correctly.

-

Test and calibrate all interfaces before flights.

-

Emergency Procedures:

-

Train pilots in handling system malfunctions.

-

Practice quick responses to unexpected situations.

-

Use simulations to prepare for real-life emergencies.

The cockpit isn’t just where pilots sit—it’s where every aspect of flying comes together. Understanding how each component works and how to upgrade them keeps aircraft operations smooth and safe.

Exploring the Deep Blue Machine

Submarines are like underwater marvels, and their hull is the key to their success. The hull is designed to withstand the immense pressure of the deep sea while keeping the sub’s insides dry and functional. Inside, you’ve got a bunch of compartments for living quarters, machinery, and even torpedo tubes. Each part of the hull is engineered to handle different pressures and conditions.

Hull Design:

-

Pressure Resistance:

-

Hulls are built to withstand deep-sea pressures.

-

Made from high-strength materials to prevent collapse.

-

Includes multiple layers for added protection.

-

Compartments:

-

Divided into sections for different functions.

-

Includes living areas, control rooms, and weapon stations.

-

Designed to maximize space and efficiency.

-

Propulsion Systems:

-

Includes diesel engines and electric motors.

-

Provides power for submerged and surface operations.

-

Features quiet operation for stealthy movements.

Diving dynamics are all about how submarines stay submerged and move around. Ballast tanks fill with water to sink the sub and pump it out to surface. Propulsion systems help the sub navigate underwater, making it a stealthy predator in the deep. The tech that keeps these systems running smoothly is crucial for a sub’s performance and safety.

Inside the Submarine’s Brain

The command deck of a submarine is where the magic happens. It’s like the sub’s brain, where all the controls, navigation systems, and communication gear are located. Here’s where the crew plots their course, communicates with the outside world, and manages the submarine’s various systems. It’s a high-tech command center with everything needed for underwater operations.

Crew Training:

-

Simulation Drills:

-

Use simulators to practice operating command systems.

-

Train crew on emergency procedures and system failures.

-

Conduct regular drills to maintain readiness.

-

System Familiarization:

-

Ensure crew members are proficient with all controls.

-

Provide hands-on training with new technology.

-

Update training materials for system upgrades.

-

Emergency Protocols:

-

Develop and practice responses to critical situations.

-

Ensure crew knows how to handle equipment malfunctions.

-

Conduct drills for emergency communication and navigation.

Communication channels are critical for submarines, allowing them to stay in touch with other vessels and command centers. Navigating underwater requires special gear to ensure accurate positioning and avoid collisions. Upgrading the command deck involves incorporating new tech to improve efficiency and capabilities, making it easier for crews to operate in challenging conditions.

The Art of Deconstruction

Torpedoes are like underwater missiles, and dissecting them reveals a world of technology. Each news torpedo has a warhead, propulsion system, and guidance controls that work together to hit targets. Understanding how these components fit together is crucial for both handling and maintenance.

Troubleshooting Tips:

When dealing with torpedoes, safety is a top priority. They contain explosive materials and sophisticated electronics that require careful handling and storage. Common issues include malfunctioning guidance systems or propulsion failures, which can be addressed with specific troubleshooting techniques.

Unraveling the Arsenal

Missiles are like high-tech projectiles, and breaking them down reveals the complexities of their design. Each missile has guidance systems, explosive charges, and propulsion mechanisms that work together to achieve their targets. Understanding these elements helps in both usage and maintenance.

Missile Components:

-

Guidance Systems:

-

Includes radar, infrared, or GPS for targeting.

-

Ensures accuracy and precision during flight.

-

Advanced systems can adapt to changing conditions.

-

Warhead Types:

-

Different warheads for various targets, such as high-explosive or nuclear.

-

Designed for maximum impact and effectiveness.

-

Secured and managed carefully to prevent mishaps.

-

Propulsion Systems:

-

Provides thrust to launch the missile.

-

Includes solid or liquid fuel engines.

-

Designed for reliable and sustained performance.

Different types of ammunition serve various purposes, from anti-aircraft to anti-tank. Each type has its own design and functionality, impacting how they’re stored and used. Preventative measures for handling munitions include regular checks and proper storage to

Beyond the Blueprint

Sometimes, it’s not about starting from scratch—it’s about revamping what’s already there. Rebuilding old war machines involves restoring them to working condition while integrating modern technology. This process can breathe new life into classic designs and extend their usefulness.

|

Aspect

|

Details

|

Benefits

|

Challenges

|

|

Restoration of Classic Models

|

- Update old designs with modern tech.

- Ensure structural integrity with new materials.

- Preserve historical elements while enhancing performance.

|

- Extends lifespan of valuable historical tech.

- Combines tradition with innovation.

- Keeps classic designs relevant in modern contexts.

|

- Balancing modern upgrades with historical accuracy.

- High cost of integrating new technology.

- Potential for technical issues during integration.

|

|

Incorporating Cutting-Edge Tech

|

- Integrate the latest electronics and sensors.

- Enhance performance with new propulsion systems.

- Improve safety features with modern materials.

|

- Boosts efficiency and effectiveness of older models.

- Provides a competitive edge with advanced features.

- Increases reliability and operational safety.

|

- Risk of technical incompatibility.

- Complexity of integrating new systems.

- Potential for unforeseen technical issues.

|

|

Innovative Design Approaches

|

- Implement new aerodynamic and hydrodynamic designs.

- Use advanced materials for better performance.

- Focus on modularity for easy upgrades.

|

- Allows for cutting-edge performance improvements.

- Provides flexibility for future upgrades.

- Enhances overall efficiency and effectiveness.

|

- Requires extensive research and development.

- High cost of experimental designs.

- Risk of unproven technologies.

|

|

Future-Proofing Techniques

|

- Design with adaptability to future technologies.

- Incorporate scalable systems for easy upgrades.

- Ensure compatibility with emerging standards.

|

- Keeps designs relevant for longer periods.

- Allows for gradual upgrades rather than complete overhauls.

- Enhances long-term value and usability.

|

- Balancing current needs with future requirements.

- Potential for increased complexity in design.

- Difficulty in predicting future tech trends.

|

Innovative integrations are about adding new tech to existing machines. This could involve installing updated avionics in older aircraft or integrating advanced sonar systems in submarines. These upgrades keep older machines relevant and capable of meeting current challenges.

Our other articles:

So, you’re ready to level up and snag yourself some superhero weapons, huh? Whether you’re looking to gear up for your own personal crime-fighting adventures or just want to flex with some next-level collectibles, you’re in the right place. But let’s be real, this ain’t just about walking into your local store and grabbing some flashy gear off the shelf.

Baca Detail

Alright, let’s dive into the wild world of tech on the battlefield—TNI style. This isn’t your grandpa’s warzone; this is where futuristic tech meets hardcore action. So, strap in, because we're about to break down how TNI is flipping the script with some insane gear and gadgets that are straight out of a sci-fi flick.

Baca Detail

Yo, welcome to the wildest reality show on the planet—Global War Drama: Who's Friends with Who and Who's Fighting Who. Forget what you know about world politics, because it’s all about who’s sliding into whose DMs, who’s throwing shade, and who’s ghosting each other on the international stage.

Baca Detail

Alright, listen up! We’ve all been there—getting a shiny new toy and then, whoops, watching it crash and burn in no time. But when it comes to military gear, those oops moments can get a whole lot messier. We're talking about some serious drama when the latest and greatest equipment hits the deck—literally. Whether it’s rookie errors, tech glitches, or just bad luck, these military mishaps can cause chaos on a whole new level.

Baca Detail

Ever seen an old-school ride get a total facelift and come out looking like a million bucks? That’s basically what’s happening with TNI’s gear these days. They’re taking classic F-16s and giving them the ultimate modern makeover, turning them from vintage legends into cutting-edge beasts. It’s like taking your grandma’s classic car and tricking it out with all the latest tech.

Baca Detail

Fanspage Militer Indonesia

Info Lengkap Pesawat Tempur

Protected by Google DMCA

Tukang Copy + Paste artikel akan dilaporkan ke Google DMCA tanpa peringatan dan tanpa pengecualian!

Top 10 Komentator

| No |

User Name |

Jumlah Komentar |

| 1 |

Admin |

575 |

| 2 |

GI |

441 |

| 3 |

Gripen-Indonesia |

413 |

| 4 |

Melektech |

389 |

| 5 |

errik |

155 |

| 6 |

iboy6 |

105 |

| 7 |

phoenix15 |

76 |

| 8 |

batik |

59 |

| 9 |

boku |

57 |

| 10 |

rezz |

54 |

Site Rating

Owner : AnalisisMiliter.com

Penulis : Admin

Rating Site : 4.2 / 5 dari 540 voters